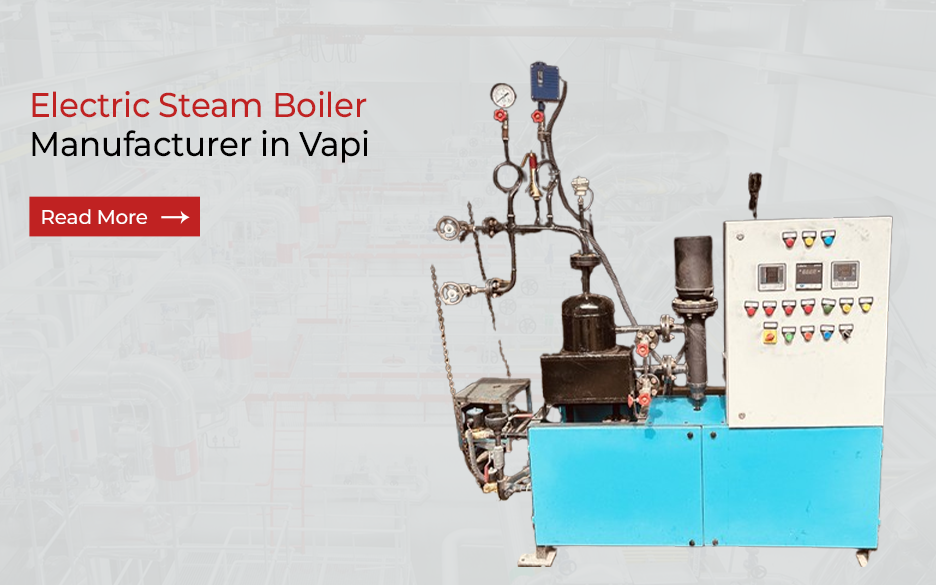

Leading Manufacturer of Electric Steam Boiler Manufacturer in Vapi, Gujarat, India

KBG Boilers Pvt. Ltd. stands out as one of the leading Electric Steam Boiler Manufacturer in Vapi, offering high-quality products for industrial applications. With a strong commitment to excellence and innovation, we are your trusted boiler parts suppliers in Vapi, catering to diverse needs across various industries. Our wide range of products ensures that we meet the stringent requirements of the steam and energy sectors, providing reliable solutions to power plants, manufacturing units, and more.

As a top boiler manufacturer in India, we specialize in the design, fabrication, and supply of premium-quality boiler parts that contribute to the optimal performance of industrial steam boilers. Our products are engineered with precision, ensuring long-lasting durability and operational efficiency, crucial for industries that rely on steam generation. Whether you are looking for pressure parts, economizers, super heaters, or other essential components, KBG Boilers Pvt. Ltd. is your one-stop destination for all boiler-related needs.

Our expertise goes beyond being just boiler parts manufacturers in Vapi; we also pride ourselves on being prominent boiler parts manufacturers in India. This national presence allows us to serve clients across the country, providing them with state-of-the-art parts and solutions. We understand the complexities of industrial boiler systems and offer tailored solutions that not only enhance system efficiency but also improve safety standards, complying with industry regulations.

As a reputed Electric Steam Boiler Manufacturer in Vapi KBG Boilers Pvt. Ltd. has expanded its footprint internationally, supplying high-quality boiler parts to various global markets. Our ability to provide cost-effective solutions without compromising on quality has earned us a strong reputation among international clients. We are trusted by industries worldwide for the manufacturing and supply of durable boiler components that stand the test of time.

At KBG Boilers Pvt. Ltd., we combine advanced technology, skilled manpower, and a deep understanding of industry needs to deliver top-of-the-line boiler parts that align with global standards. Our manufacturing process incorporates cutting-edge techniques to ensure that every part is crafted to perfection.

FAQs

Here are 5 differences in the FAQ about boiler parts manufacturers in Vapi, featuring "KBG Boilers Pvt. Ltd.":